PU 11: What Happened to UPS Flight 2976?

On 4 November, an MD-11 cargo plane operated by UPS crashed in Louisville, Kentucky, killing fourteen people. We know that the airplane lost its left engine on take-off. But why did that happen?

N259UP taking off during the accident flight, its No. 1 engine missing, the left wing engulfed in flames (UPS)

Subscribe to podcast:

Transcript

This is Punching Upwards episode 11 for the 23rd of November 2025. What happened to UPS flight 2976? Broadcasting from the vicinity of Echo Delta Delta Lima, Düsseldorf Airport, where ceiling and visibility are okay, with nine knots of sullenly wind in a surface trend pressure of two degrees Celsius, my name is Fab and I’m your host for this podcast. Welcome to Punching Upwits. On this episode of the show, I want to provide a detailed look on the crash of UPS Flight 2976 in Lewisville, Kentucky on the 4th of November 2025. Reports in the legacy media have basically been limited to the left engine fell off the plane and it crashed in a huge fireball. But I want to know how exactly it crashed and why. On this episode, I will let you know what I have discovered so far. The content of this episode is largely based on the preliminary report on the accident released by the National Transportation Safety Board, NTSB, of the US.

It is important to keep in mind that this preliminary report leaves many questions unanswered and that we will probably only have them answered once the NTSB’s final report is released. But since the preliminary report already includes many important details, I thought it useful to record an episode on what we know so far.

The final report usually takes another year or so to come out. The NTSB is incredibly thorough, but that thoroughness means that their work takes time. Legacy Media tends to report the facts, but never really goes deep enough to explain anything. This triggers emotions, mostly fear and anger, but doesn’t really help you to understand what happened and why.

As an example, here’s an NBC Nightly News report from this week on the release of the NTSB preliminary report.

The NTSB photos released today show the left engine and the pylon holding it to the UPS plane’s wing, coming off the plane as it began to take off. Then a massive fire as the engine exploded up and over the fuselage, dooming the three pilots on board and killing 11 people on the ground.

Mothers, fathers, sons and daughters, husbands and wives. This might be the toughest Thanksgiving that their families have ever been through. In the plane’s remains, the NTSB says, investigators found fatigue fractures in the pylon structure holding the engine to the wing, there and there with green arrows. As the NTSB notes, haunting similarities to a 1979 crash involving the previous model of the same plane that killed everyone on board.

This is all that was left of American Airlines Flight 191, as far as it got on its way to Los Angeles. Investigators later determined the engine and pylon came off that plane after being damaged during maintenance. The FAA quickly ordered regular inspections of similar planes. The UPS plane that crashed in Louisville, built in 1994, went through routine maintenance in October, but wasn’t yet due for a heavy, detailed pylon inspection.

The similarity of the engine and pylon coming off the wing is too obvious just to ignore. But the details of how that happened, well, that’s something the NTSB is going to be challenged with.

All right. And Tom, that plane in question, the MD-11 has been grounded. Both FedEx and UPS rely on that. Is that impacting their operations going into the holidays? Yeah, a little bit. Right. They both had to use smaller planes, lean on partner airlines and ground transport options to help carry packages. Yeah, they’ve had some delay already in shipping, but they both hope to be operating normally as they approach Christmas, Tom.

Ignoring the implications for holiday shopping, let’s dive deeper here and figure out as much as we can about this tragedy so that we may actually understand what happened as best as it is currently possible. Settle in and grab a coffee. This one will be detailed. On the 4th of November 2025, a McDonnell Douglas MD-11F, operated by UPS, was planning to fly from Louisville, Kentucky to Honolulu, Hawaii. Louisville, Muhammad Ali International Airport, Kilo, Sierra Delta Foxtrot. houses UPS’s worldwide flight hub, and the airplane was loaded to its maximum cargo capacity for its over nine-hour-long flight over to Hawaii.

The McDonnell Douglas, now Boeing MD-11, is a trijet, an airliner that has two underwing engines and a third one mounted on the base of the vertical stabilizer. This aircraft design was popular in the 60s, 70s, and 80s, but has since fallen out of favor. The MD-11 is a white-body aircraft and the largest trijet ever built. This is an updated version of the McDonnell Douglas DC-10, which was a common sight in the skies in the 70s and 80s, but fell out of favor with the public due to a number of high-profile accidents, including the worst aviation disaster on U.S. soil to date. More on this later. The MD-11 was eventually retired from passenger service by all airlines operating it by the early 2000s.

This was not due to accidents, of which the MD-11 also had a few, but due to the fact that its design didn’t bear out the promised fuel consumption rates. Compared to its contemporary two-engine competitors, the MD-11 was overpowered and used a lot of fuel. The ICAO, the International Civil Aviation Organization, has a group of safety standards called ETOPS – Extended Range Twin Engine Operation Performance Standards. Because in aviation it is always assumed that one jet engine on a plane can fail, ETOPS specifies the route a twin-engine aircraft must take in isolated areas to keep close to alternate runways it can divert to in case one of its engines fails. For this reason, long-haul flights over oceans and remote territories were traditionally only performed by tri- or quad-engine jets like the DC-10 and the Boeing 747. But in the late 90s and early 2000s, the ICAO began to relax these rules and twin-engine jets became much more common and eventually took over on long-haul flights. Now there are twin-engine planes like the Airbus A350 rated for ETOPS 370, which means it is approved for single-engine operation up to 370 minutes, which is over six hours of flight time.

Meaning it can fly routes where its maximum flight time to the nearest airfield is six hours, across the Pacific Ocean, for example. Technically, ETOPS has now been renamed EDTO, Extended Diversion Time Operations, and also includes quad-engine jetliners. Due to this new ability for twin jets to fly over ocean routes and their more fuel-efficient designs, all remaining passenger MD-11s were converted to MD-11Fs and entered freight service, where the plane’s power can better offset its fuel consumption than in passenger operations. Boeing stopped production on the plane in 2000, a few years after it had acquired McDonnell Douglas, because the MD-11 was competing with its own designs.

At the moment, there are three MD-11 operators left. FedEx operates 28 aircraft, UPS-26, and Western Global Airlines, another freight airline, operates 15 aircraft. But back to Louisville, Muhammad Ali International Airport, Kilo, Sierra Delta Foxtrot. On 4th of November, when UPS MD-11 is about to take off for Hawaii to perform flight 2976.

The plane is fully loaded with cargo and there are three crew on board. A captain who will be pilot monitoring for the flight, first officer, the pilot flying, plus a reserve captain. The reserve captain in the jump seat is there because of the length of the flight.

He’s scheduled to take over from the first officer a few hours into the nine-hour trip to Hawaii. The captain had 8,613 total flight hours, of which 4,918 hours were on the MD-11. The first officer had 9,200 total flight hours, with 994 hours on type.

The reserve captain had 15,250 total hours of flight experience and 8,775 hours on type. With other words, this is a very experienced crew and they knew this aircraft type very well. The reserve captain was actually one of the most experienced MD-11 pilots in the company. The MD-11 lined up on runway 17R and received takeoff clearance from Louisville Tower at 17.11 local time. It started accelerating down the runway and all seemed well until rotation, when as soon as its wheels left the tarmac, the left wing was engulfed in huge flames.

The aircraft initially climbed a bit, cleared the blast fence at the end of the runway, but then its left landing gear clipped the roof of a UPS warehouse. The aircraft flew on and then rolled over on its left side, impacting a petroleum recycling facility and created a huge fireball and a debris field almost a kilometer long. All three crew on board the aircraft and 11 people on the ground at the Kentucky Petroleum Recycling Company and the Grade A auto parts, semi-truck parking lot and scrap yard were killed. 23 people on the ground were injured. Luckily, the flight carried no hazardous cargo. Airport personnel immediately noticed the plane’s number one engine, pylon still attached, laying on the grass on the right side of runway 17R.

Aside from major damage from the fall, the engine core seemed to be largely intact. What exactly had happened? According to the NTSB’s preliminary report, which I have linked in the show notes to this episode, listed at fab.industries slash podcast, the takeoff was uneventful until the plane reached its VR speed and the pilot rotated the aircraft.

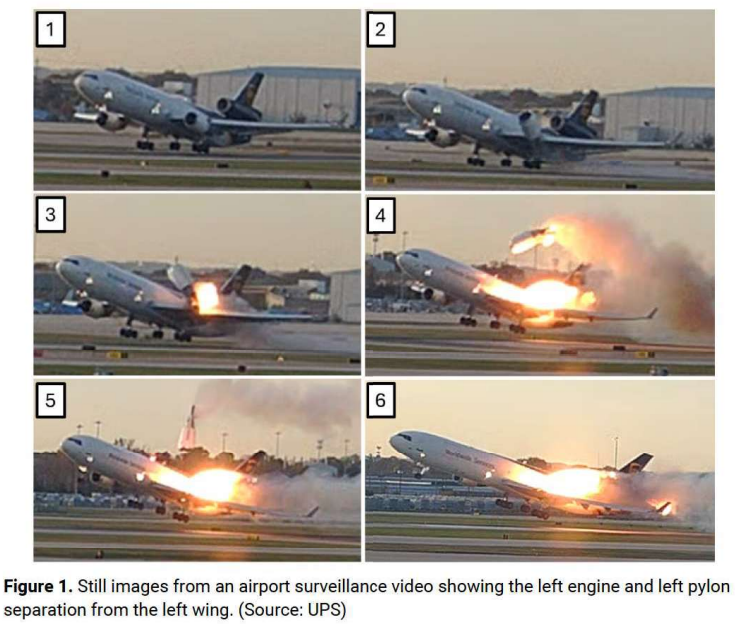

The NTSB has a striking series of screenshots from an airport surveillance video that show very clearly what happened next. I have included these photos in the show notes and it might well pay to pull them up right now to visualize what I will be discussing next.

This is a series of six screenshots showing the airplane from about a 45 degree angle from the front, showing the left wing of the aircraft. Now, to understand the following discussion, it is important to know how engines on an aircraft are numbered. From the vantage point of the cockpit, looking ahead, engines are numbered left to right, meaning the engine mounted under the left wing of the MD-11 is engine number one, the one mounted in the middle of the plane at the base of the vertical stabilizer is number two, and the engine on the right wing is engine number three. In the first screenshot, you can see the aircraft right after rotation.

And rotation is basically the point when the aircraft takes off, where the pilot pulls the stick back, lifts the wheel with the wheels of the tarmac. That’s called rotation. So back to the first screenshot, where you can see the aircraft right after rotation. The gear has just left the ground. If you look carefully, you can see that engine number one is already starting to tilt upwards a bit. In the second screenshot, you can clearly see The number one engine together with its pylon breaking off the wing and flipping up and over. There is gray liquid or aerosol or baby smoke visible spilling from the engine.

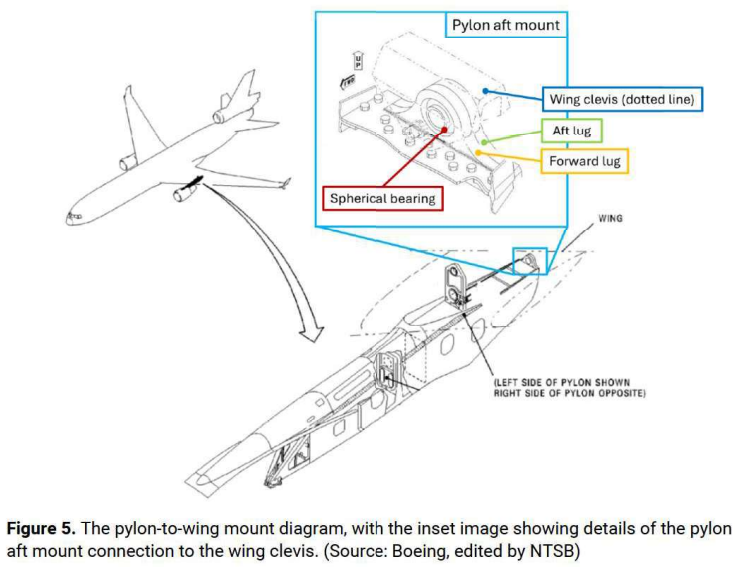

n case you don’t know what an engine pylon is, here’s a little explanation. That’s the spar that extends from the underside and front of the wing outwards towards the front of the plane which the underwing engines are mounted on. The way it works is that the engine is bolted to the pylon and the pylon in turn is attached to the wing. The pylon’s job is to project the engine forward and below of the actual wing. And it also houses electric cabling, fuel and hydraulic lines leading from the engine to the wings and the airframe. The pylon is also designed in a way that transfers forces from the engine, especially under full thrust, to the airframe so that this force will not shake the engine apart.

In the third screenshot, you can see the hot exhaust gases exiting the still running engine, which is in the process of flipping over the wing and fuselage of the plane, igniting what is probably jet fuel leaking out of the severed fuel lines leading from the winged tanks to the now separated engine. Image 4 shows a fire starting on the top of the left wing, probably caused by fuel spilled there from the severed engine. It also shows the severed engine and pylon flying in a big arc, high across the fuselage, trailing smoke and fire. In the fifth screenshot, you can clearly see the engine with the attached pylon at the top of its arc over the plane, now dropping on the right side. The fire on the engine is out and it’s trailing smoke. This explains why the engine was found on the right side grass margin of the runway.

It had flipped over the wing and clear across the fuselage of the departing plane. During all of this, the plane continues to rotate, its left wing now fully engulfed in flame. In the sixth image, the number one engine is obscured by the plane, still dropping, while the MD-11 continues to struggle in its takeoff, while its left wing is sprouting a huge flame, fueled by the kerosene that continues to spray out of the savage fuel line on the left wing. In images 3 and 4, the aircraft is clearly exhibiting a yaw to the left, caused by the resulting drop in thrust on its left side as the engine is ripped off.

Images 5 and 6 show the pilot immediately correcting to the right, probably after hearing a bang and noticing this jaw to the left. It is important to know that the engines are not visible from the cockpit, and if an engine rips off like this, there will probably be no clear indication of what happened in the cockpit.

The engine performance indicators will drop to zero, and there might be engine malfunction indications. Not to mention that some instruments in the cockpit might initially stop working after losing power from the generator in the number one engine. But some of this might initially be suppressed, and even the fire warning will not sound until the aircraft reaches 400 feet above ground. which this aircraft never did. This is because pilots are trained not to troubleshoot or even concentrate on any issues with the plane’s equipment below 400 feet. In training, it is drilled into them that under 400 feet, the only priority is to keep the airplane flying and reach an altitude of at least 400 feet.

That is because under this altitude, it’s much too dangerous to do anything else than concentrate on flying the aircraft, especially in emergency situations with things like fires or an engine malfunction. So in this case, it is very likely that the pilots, during their one-minute flight, never realized what the problem was. They probably didn’t know that their number one engine had detached or that their left wing was on fire. It is quite obvious why the separated engine goes over the wing and not under it, since it’s generating thrust and has no wings itself, so it would normally, not attached to anything, take off vertically, like a rocket. But why did it flip over the fuselage towards the right? Well, this is due to a phenomenon called gyroscopic precession. Since the fan of the engine is essentially a gyroscope, it will exhibit the same kind of physical forces.

A gyroscopically spinning disc tends to want to accelerate 90 degrees off to the side from the direction that force is applied. Because the fan rotor in this engine is spinning anti-clockwise on GE engines, this means that looking at the engine and fan from the top towards the direction of flight, the gyroscopic precession tilts the spinning fan disk to the right. This is why the engine flew up and backwards and started rotating to the right, cartwheeling over the top of the plane’s fuselage. In the preliminary report, the NTSB comes to the conclusion that the number one engine fell off the wing due to fatigue cracks on the aft connection point between the engine pylon and the wing. Because stresses on an engine and its mounting structures are biggest during the rotation at takeoff, it seems likely that these fatigue cracks finally gave out on this takeoff.

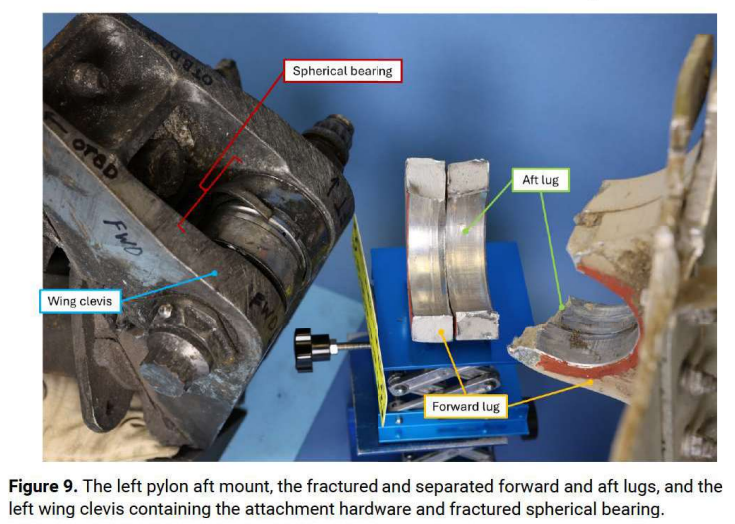

This caused further stress fractures in other places in the aft connection point, which then catastrophically failed. The engine pylon is connected in two points, front and aft, to a part in the wing called the wing clevis. When the aft connection point failed, the engine and pylon began to flip upwards over the wing and also ripped off the front connection point and then the engine flew off. The other underwing engine, number three, remained attached to its pylon and the pylon remained attached to the wing until the plane crashed into the ground. So far as we know, the number three engine pylon had no similar fatigue cracks in its pylon mount.

Quoting from the NTSB preliminary report about the failure of the number one engine pylon mount. The left number one and right number three engines of the MD-11 airplane are attached to the underside of pylons that are in turn attached to the underside of each wing. The left and right pylon attaches to their respective wing via forward mount bulkhead, a thrust link assembly and an aft mount bulkhead. For simplification, this report will refer to these bulkheads as the forward mount and the aft mount.

The forward mount contains two spherical bearings that are vertically aligned, upper and lower, that attach to the wing. The thrust link assembly located immediately behind the forward mount’s lower spherical bearing primarily transmits thrust loads. The pylon aft mount is an assembly composed of two independent fittings bolted together with lugs, forward lug and aft lug that house a single spherical bearing. For this report, references to the pylon aft mount spherical bearing includes both the bearing’s ball element, sphere, and its outer race.

A clevis on the underside of each wing, called the wing clevis, connects to the pylon aft mount via attachment hardware. The left pylon aft mounts forward and aft lugs were both found fractured near their 2 o’clock inboard fracture and 9 o’clock outboard fracture positions when in the aft looking forward frame of reference.

After initial cleaning of the fracture surfaces, examination of the left pylon aft mount lug fractures found evidence of fatigue cracks in addition to areas of overstressed failure. On the aft lug, on both the inward and outward fracture surfaces, a fatigue crack was observed where the aft lug bore met the aft lug forward face.

For the forward lug’s inboard fracture surface, fatigue cracks were observed along the lug bore. For the forward lux output fracture surface, the fracture consisted entirely of overstress with no indications of fatigue cracking. So, from this, it seems pretty clear that existent metal fatigue met a point of no return on this particular takeoff that caused the whole left pylon aft mounting assembly to fail. But was it simply due to the stress of rotation or did the engine have a malfunction that initiated this failure? We simply don’t know this yet and probably need to wait for the NTSB final report for an answer.

The NTSB found detached fan blades with the rack of the number one engine. but it isn’t at all clear if those came loose during the crash of the engine when it impacted the ground or possibly before. The CF680 series of engines does have a history of uncontained engine failures, something that could have caused serious vibrations, which in turn could have caused the aft pylon attachment to fail due to the already present fatigue cracks.

But with the data we have available right now, we simply can’t tell if the engine experienced a problem which caused it to rip the pylon mounting apart or if the pylon mounting simply failed due to the stress during aircraft rotation. At the time of the accident, the aircraft in question, registration November 259er, Uniform Papa, was 34 years old. It had been delivered as a passenger jet to Thai Airways in 1991. at a registration at this time Hotel Sierra Tango Mike Echo. UPS bought it in 2006 and converted it to a freighter.

It entered freight service for UPS in 2007. This was an old and well-used aircraft. The airframe had accumulated 92,992 hours of flight in 21,043 cycles. cycle being one takeoff and subsequent landing. The last visual inspection of the left pylon mount had taken place on the 20th of October 2021.

A 24-month or 4,800 flight hours lubrication task of the pylon thrust links and pylon spherical bearings was last done on the 18th of October this year. It is however not clear to me if this lubrication task included a visual inspection of the components that failed or if it necessitated removal of the pylon from the wing, a procedure that could have damaged the pylon’s aft connection point. More on this later. A special detailed inspection, a so-called SDI, of the left pylon aft mount lugs would have been due at 29,200 cycles and of the left wing clevis support at 28,000 cycles.

But with 21,043 cycles on the airframe, these were not due yet and hadn’t been performed. On the 8th of November, the FAA issued Emergency Airworthy Directive 2025-2351, grounding all MD-11 planes. On the 11th of November, the FAA issued Emergency AD 2025-2353, which also grounded all DC-10 aircraft based on the fact that their design is similar to the MD-11, especially when it comes to the engine and pylon mountings on the wings.

Remember when I talked about how the public lost trust in the DC-10, the plane that McDonnell Douglas based the design of the newer MD-11 on? This is due in part to two incidents where the cargo door was ripped off passenger versions of the DC-10 in the 70s, causing the loss of life of 346 passengers and crew in the case of Turkish Airlines Flight 981 when it crashed shortly after takeoff from Paris or the airport in France in 1974. But the bigger disaster came with American Airlines flight 191, to date the deadliest aviation accident on US soil.

On the 25th of May 1979, a DC-10 taking off from O’Hare International Airport in Chicago lost its left number one engine on takeoff rotation. The airplane was initially able to climb with its two remaining engines and reached a height of about 325 feet before it weared to the left, stalled and crashed.

There was no fire on the left wing, but the wing was clearly leaking fuel and what was later discovered to be hydraulic fluid. The NTSB final report on that accident determined that the detachment of the left pylon had severed hydraulic lines that caused the slats on the left wing to retract under air load.

This raised the stall speed of the wing to a speed higher than the takeoff speed of the aircraft. The aircraft’s left wing stalled, and the pilot didn’t realize what was happening because the stick shaker responsible for warning the pilot when the airplane stalls was inoperative due to the loss of the generator in the engine that had detached.

This is why he didn’t understand that his aircraft was stalling, didn’t initiate a maneuver to counteract it, and the plane rolled over to its left in an uncontrollable dive and crashed. In case you don’t know what slats are, here’s a short explanation. They are wing leading-edge devices analogous to the better-known flaps.

Pilots lower flaps at the back of the wing and slats at the front of the wing on jetliners on takeoff and landing to allow the plane to fly at lower speeds without stalling. This is necessary because the wing profile of these planes is designed to provide lift at the higher cruising speeds of the plane.

Without flaps and slats, the wing shape doesn’t provide enough lift to keep the plane in the air at lower speeds during takeoffs and landings. In the case of the DC-10 performing American Airlines flight 191, the number one engine went up and over the wing, but landed on the left side of the runway with its pylon still attached.

Robert Graham, supervisor of maintenance for American Airlines, who witnessed the takeoff in question, said, quote, As the aircraft got closer, I noticed what appeared to be vapor or smoke of some type coming from the leading edge of the wing and the number one engine pylon.

I noticed that the number one engine was bouncing up and down quite a bit, and just about the time the aircraft got opposite my position and started rotating, the engine came off, went up and over the wing, and rolled back down onto the runway. Before going over the wing, the engine went forward and up, just as if it had lift and was actually climbing. It didn’t strike the top of the wing on its way. Rather, it followed the clear path of the airflow of the wing up and over the top of it, then down below the tail. The aircraft continued a fairly normal climb until it started to turn to the left.

And at that point, I thought he was going to come back to the airport. Obviously, the plane crashed in a field outside the airport. The DC-10’s pylon attachment structure, shown in the NTSB’s final report on American Airlines Flight 191, which is also linked in the show notes, looks remarkably similar to the same structure on the MD-11.

According to the report, the left pylon of the DC-10 detached because the pylon aft mount failed. In this accident, there was also a sign of metal fatigue. However, the NTSB determined that the pylon aft mount had been damaged during maintenance and that this caused metal fatigue, which later caused it to fail.

This was because American Airlines used a maintenance procedure that damaged the pylon. The engine manufacturer had specified the engine to be removed from the pylon for maintenance. But American Airlines and other DC-10 operators decided instead of detaching the engine from the pylon, they would detach engine and pylon together from the wing because this would save time and thus money. Some airlines, including American, used a forklift for this procedure to hold the engine up during detachment from the wing. The maintenance workers damaged several DC tents by mistake. In all cases, the forward fittings had been removed and accidents happened while the pylon was held to the wing by the aft detachment only.

This was due to several errors of forklift handling or the forklift unexpectedly moving downwards under the weight of the engine and pylon. These accidents were usually detected and the mounting repaired. The NTSB concluded that the accident aircraft had such an accident happen in the maintenance, but that nobody had repaired the resulting damage for some reason, therefore leaving the structural integrity of the pylon mount compromised. After the accident, all DC-10s in service were inspected, and several of them showed familiar fatigue damage to the accident aircraft that would have sooner or later led to the pylon in question detaching from the aircraft.

While there are several striking similarities in the UPS Flight 2976 and American Airlines Flight 191 disasters, enough to also have the NTSB include a quick summary of the latter crash in the current preliminary report, there are also some important differences. Both the DC-10 and MD-11 are three engine planes, which means they should be capable of sustaining flight after losing one engine. And in the case of the DC-10 in 1979, we can see that the airplane would have actually managed to continue flying had it not been for the left wing stall, which was due to the retracted slats on that wing. Meaning the pilot could have saved the plane by increasing speed. In case of the MD-11 crash this year, the plane did not crash due to wing stall.

Even though the wing was completely engulfed in fire, the plane obviously never managed to climb, never getting above about 30 feet. This would lead one to believe that a second engine failed on the aircraft. Video footage clearly shows the right number three engine working, so there have been speculations that the number two engine failed, possibly to a compressor stall or surge after ingesting debris or maybe jet fuel from the detached number one engine. The way in which the detached engine spiraled over the hull right in front of the number two engine clearly makes that a possibility. It flopped to the ground behind the number three engine, so that one wasn’t impacted.

Note also how in the American Airlines accident, the detached engine and pylon didn’t cross over the fuselage, so they had nothing compromising their number two engine. These tail-mounted engines have also been known to be more susceptible to compressor stalls than the wing-mounted ones. But so far, the preliminary report doesn’t make it clear if engine number two was working or not. Since the aircraft was fully loaded with cargo, basically at its takeoff weight limit, this would also have been a factor, making a climb harder than for the American Airlines DC-10 in any event.

We also don’t know why the aft pylon attachment failed in the case of the UPS MD-11. Did something happen at the lubrication task of the pylon thrust links and pylon spherical bearings on the 18th of October? Or was it simply structural failure because this was a plane that had been used a lot and under very taxing conditions? For definite answers, we will have to wait for the NTSB’s final report. This will probably take the best part of another year. But since the NTSB has verified that they’ve gotten the relevant data from both the flight data and cockpit voice recorders, they should have the means of figuring out what happened.

Until we know why the pilot attachment failed and what caused the plane to be unable to climb with its other two engines, I would expect all MD-11s and DC-10s to remain grounded. So in conclusion, we know that the left engine separated from the airplane because of stress fractures in the aft pylon mount.

But we don’t know if that was the only reason, i.e. was it just the rotation of the airplane that caused that? Or maybe was there an engine malfunction? on the number one engine as well, which made this whole worse by causing vibrations or something like that. And then crucially, we also don’t know why they, even with that engine having fallen off the plane, couldn’t climb with the other two engines as the aircraft was designed to do. So we don’t know if maybe the number two engine was also impacted by debris from the number one engine or maybe fuel that it ingested or something like that.

So in comparison to the earlier crash in the 70s with the DC-10, obviously they were able to climb and they then had another problem, which this MD-11 didn’t seem to have. I will, of course, update you on further episodes if we learn anything new of significance in this case. Thanks to Michael Mull-Jensen and Fadi Mansoor for subscribing to the podcast on Substack and supporting it financially. Additional thanks to Sergal Taren, who continues to provide hefty financial backing via Fountain.fm. If you want to join these good people in making sure that I can keep making these episodes, head to fab.industry slash podcast.

This page not only tells you how to get the show via various podcast apps, it also explains the Substack subscription. That way you’ll get an optional email when a new episode is released and you’ll be supporting me with a subscription of 5 euros a month or 50 euros a year plus tax. or whatever your local equivalent currency is. Thanks for listening to this episode of Punching Upwards. The theme music for the podcast is a track called Fight or Fall by DevLev, which is used under license. I will be back with more detailed coverage of interesting news stories that you won’t get from the corporate news media next Sunday.

Until then, goodbye and good luck. This has been Punching Upwards, a podcast by Fab Industries. New media, new rules.

Clickable transcript on Substack episode page

Credits

Thanks to Michael Mullan-Jensen and Fadi Mansour for subscribing to the podcast on Substack and supporting it financially! Additional thanks to Sir Galteran who continues to provide hefty financial backing via Fountain.fm!

Sources

- Aviation Investigation Preliminary Report DCA26MA024 (UPS Flight 2976), NTSB, November 2025

- Crash: UPS MD11 at Louisville on Nov 4th 2025, burst into flames on takeoff, The Aviation Herald, 5 November 2025

- NTSB releases new images and preliminary report on UPS cargo plane crash, NBC News, 21 November 2025

- Aircraft Accident Report AAR-79-17 (American Airlines Flight 191), NTSB, December 1979

- Gyroscopic Precession, AOPA Foundation, 29 January 2012

- Extended Diversion Time Operations (EDTO) Manual, ICAO, 2017

- Owner’s & Operator’s Guide: MD-11 Family, Aircraft Commerce, Issue 47, August 2006

- MD-11 Flight Crew Operations Manual, Revision 58KL, KLM – Royal Dutch Airlines, 16 November 2009

The theme music for the podcast is a track called Fight or Fall by Def Lev. Find out more about the show at fab.industries/podcast — new media, new rules!